At Shaw Industries and Welding Technologies, we specialize in the production of high-quality forging dies and components, crucial for various industrial applications. Our expertise in die fabrication ensures that each component meets the rigorous demands of modern manufacturing processes. Utilizing advanced materials and precision engineering, we create forging dies that deliver exceptional performance and durability.

Our process begins with a comprehensive design phase, where we collaborate closely with clients to understand their specific requirements and operational challenges. Using state-of-the-art CAD software, our engineers develop detailed plans that ensure optimal functionality and longevity of the forging dies.

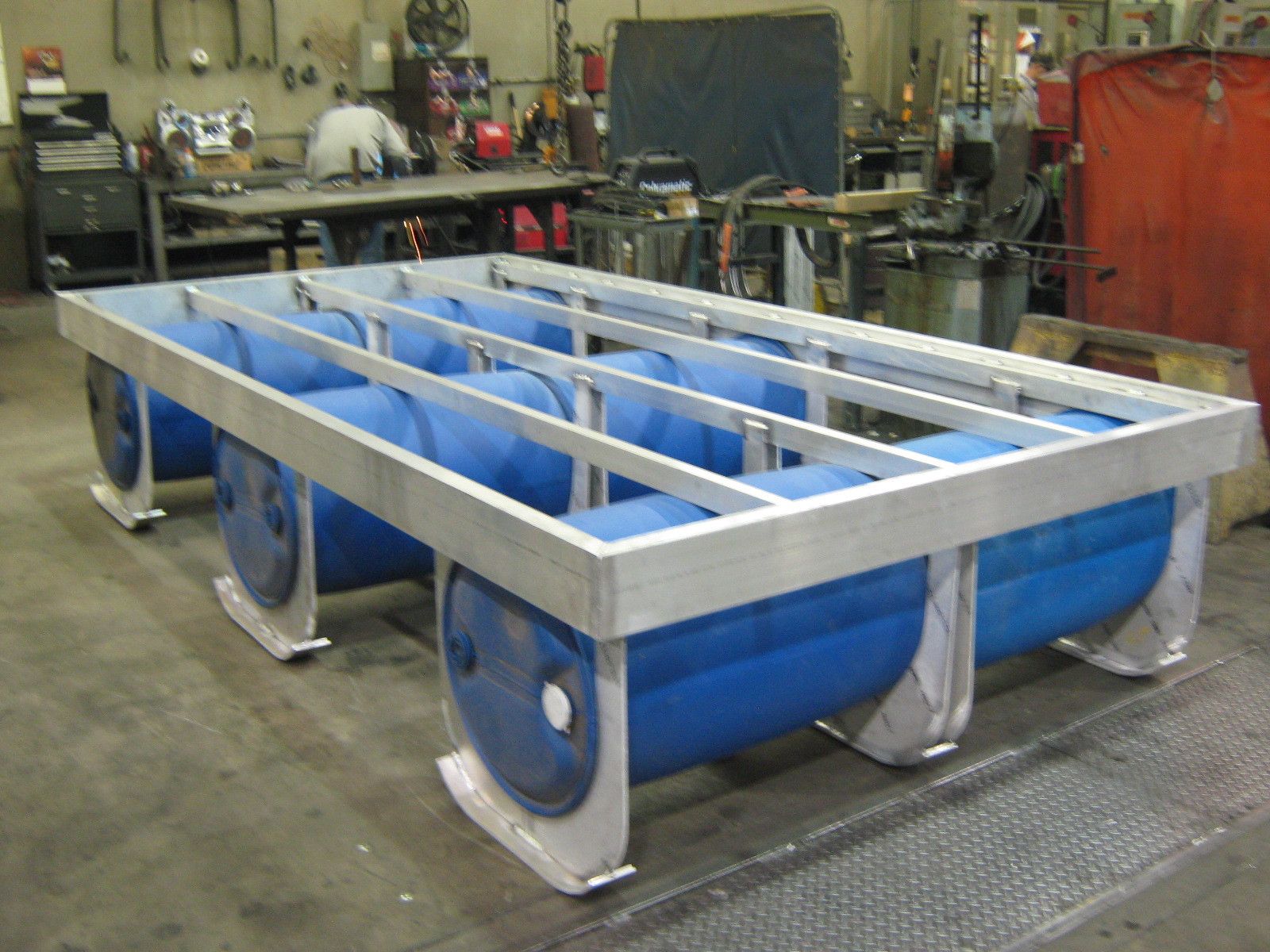

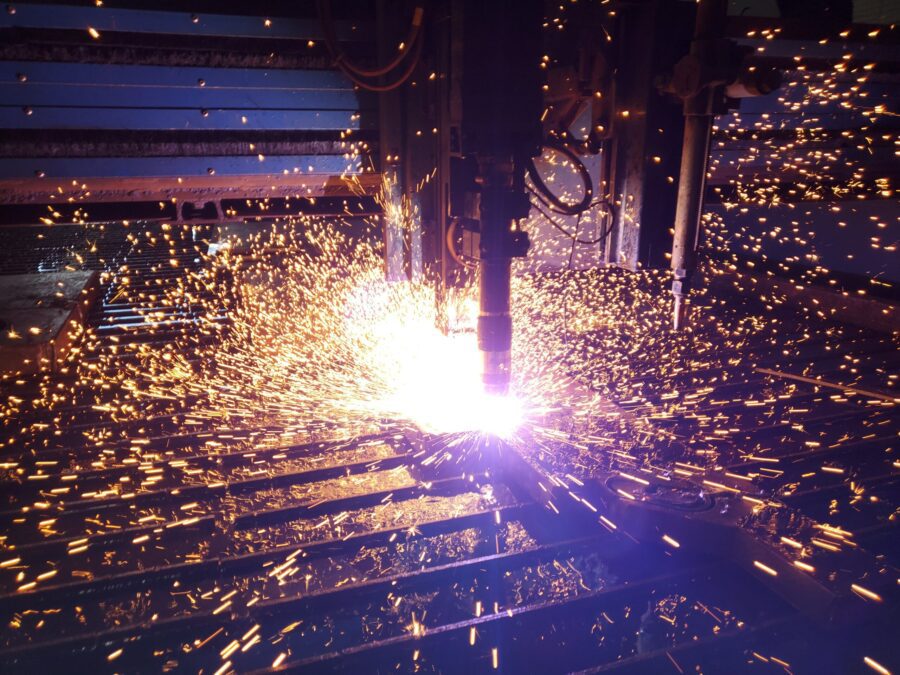

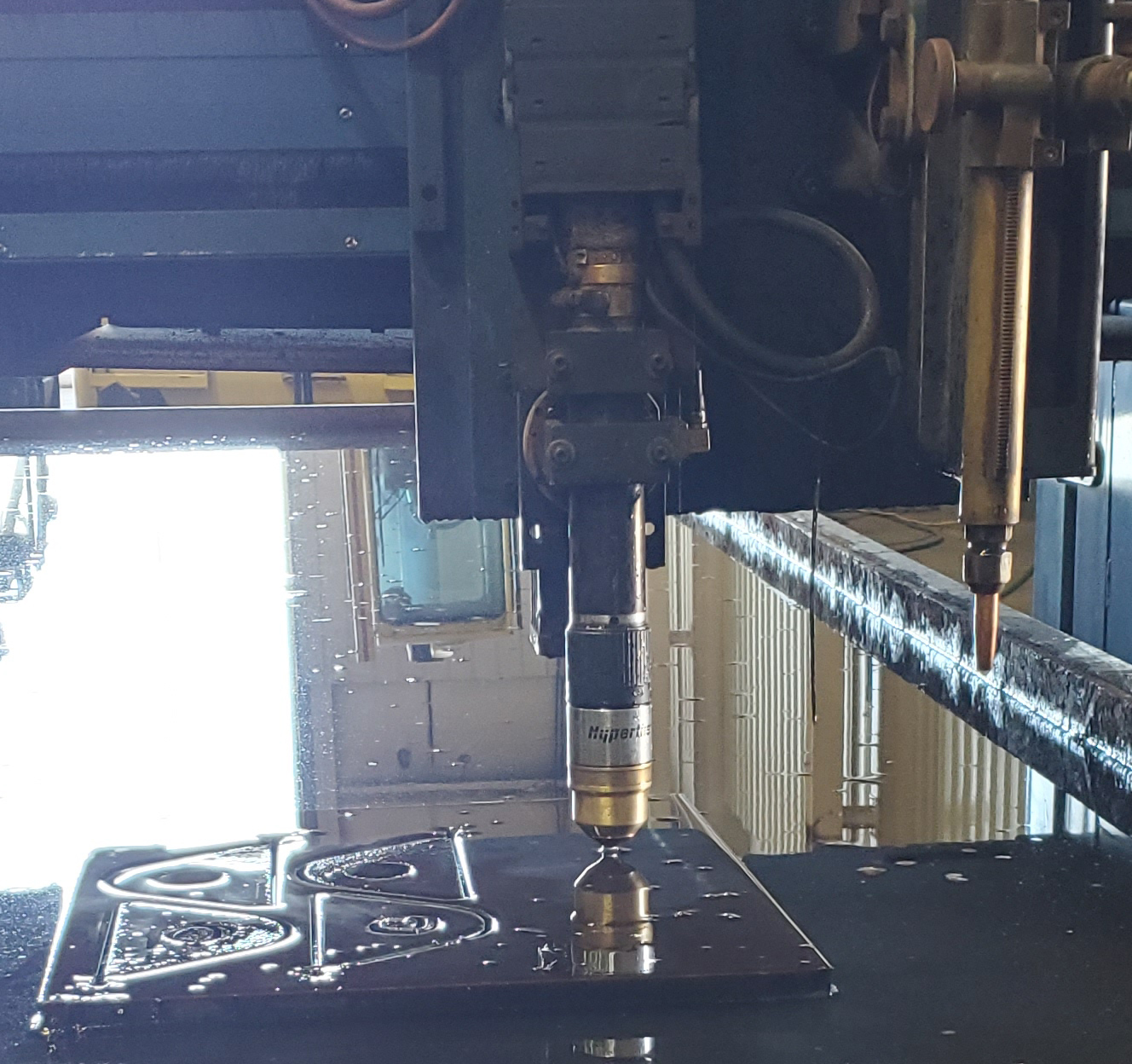

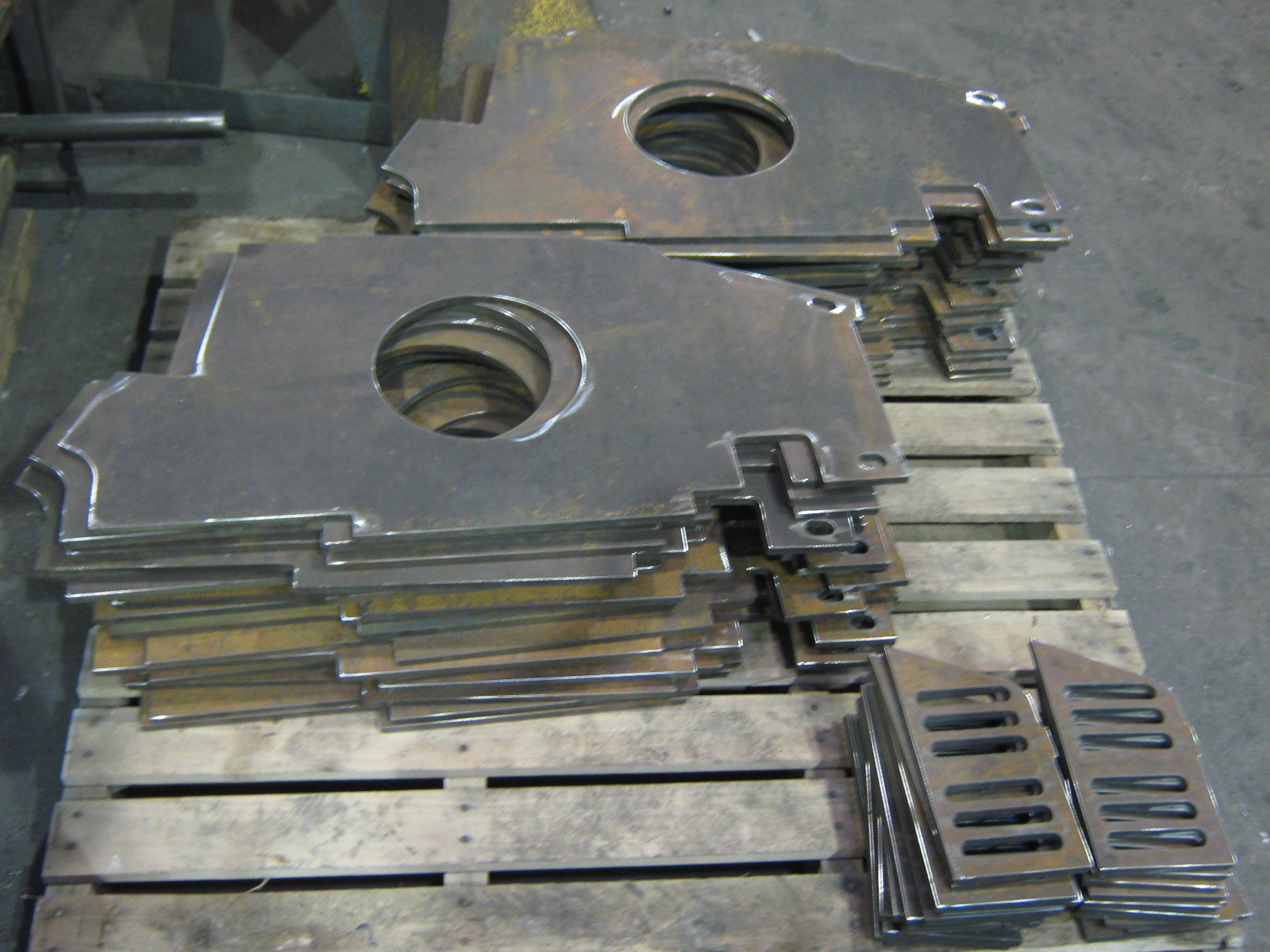

Once the design is finalized, our skilled machinists and fabricators get to work. We use high-grade tool steel and other robust materials, carefully selected for their strength and resistance to wear. Our precision machining capabilities allow us to achieve exact tolerances, ensuring that each die and component performs flawlessly in high-pressure forging environments.

During the forging process, we apply advanced heat treatment techniques to enhance the hardness and durability of the dies. This ensures they can withstand repeated use and maintain their integrity under extreme conditions. Our rigorous quality control measures, including dimensional inspections and performance testing, guarantee that every forging die and component we produce meets the highest industry standards.

At Shaw Industries and Welding Technologies, we are committed to delivering top-tier forging solutions that enhance the efficiency and productivity of your operations. Contact us today to discuss your needs and receive a quote for our forging die and component services. Trust us to provide reliable and precise solutions tailored to your specific requirements.