Inspection Capabilities

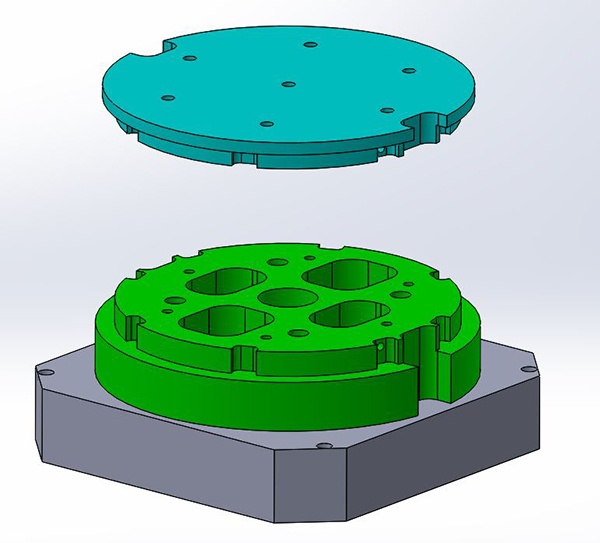

At Shaw Industries and Welding Technologies, we leverage the power of SolidWorks 2022 and ESPRIT to establish a fully integrated CAD/CAM system that revolutionizes our design and programming processes. SolidWorks 2022, a leading CAD software, enables our engineers to create detailed and precise 3D models with unmatched accuracy. Its intuitive interface and robust feature set allow for efficient design iterations, ensuring that every component is optimized for functionality and manufacturability. The advanced simulation capabilities of SolidWorks 2022 enable us to test and validate designs under real-world conditions, reducing the risk of errors and enhancing the overall quality of our products.

Complementing SolidWorks 2022, ESPRIT provides powerful CAM functionalities that seamlessly integrate with our CAD designs. ESPRIT’s advanced machining capabilities and intelligent automation features allow us to generate highly efficient toolpaths and machining strategies directly from our SolidWorks models. This integration ensures a smooth transition from design to manufacturing, minimizing downtime and maximizing productivity. The combination of SolidWorks 2022 and ESPRIT enables us to maintain tight tolerances, optimize material usage, and deliver superior products with consistent precision. Together, these tools form the backbone of our design and programming operations, allowing Shaw Industries and Welding Technologies to meet the diverse and demanding needs of our clients with unparalleled efficiency and reliability.

At Shaw Industries and Welding Technologies, our trucking capabilities are robust and versatile, ensuring efficient transportation of materials and finished products. We operate an International Triaxle with a 26-foot flatbed, a Ford F600 with a 12-foot flatbed, and a Ford F550 with a 12-foot flatbed, allowing us to handle a wide range of load sizes and configurations. For loads that exceed our in-house trucking capabilities, we maintain strong affiliations with local trucking firms, ensuring we can accommodate any transportation needs our clients may have. This combination of in-house and partnered resources allows us to provide reliable and timely delivery services for all our projects.

At Shaw Industries and Welding Technologies, our lifting capabilities are designed to handle a wide range of heavy-duty tasks with precision and efficiency. Our facility is equipped with 33 overhead cranes, with capacities ranging from 1 to 20 tons and a maximum height of 18 feet 6 inches under the hook. Additionally, we have 8 forklifts, each with up to a 4-ton capacity, ensuring we can safely and effectively move large and heavy components throughout our workspace. These robust lifting solutions enable us to manage even the most demanding projects with ease, maintaining the highest standards of safety and performance.