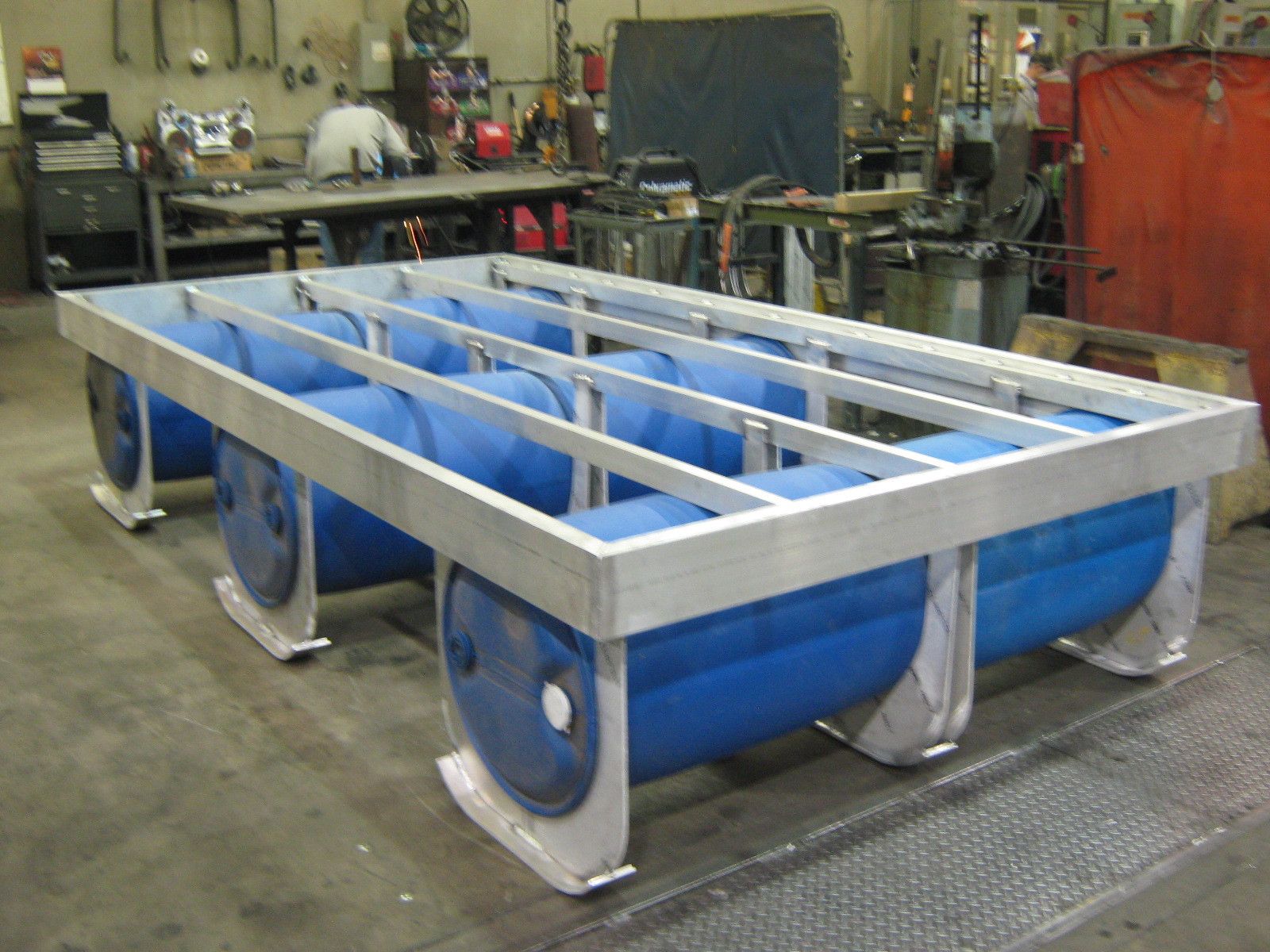

At Shaw Industries and Welding Technologies, our fabrication services are designed to meet the highest standards of quality and precision. Our skilled team of fabricators begins each project with a thorough understanding of the client’s specifications and requirements. We work with a variety of metals, including steel, aluminum, and stainless steel, ensuring that each piece is tailored to meet the unique needs of your project.

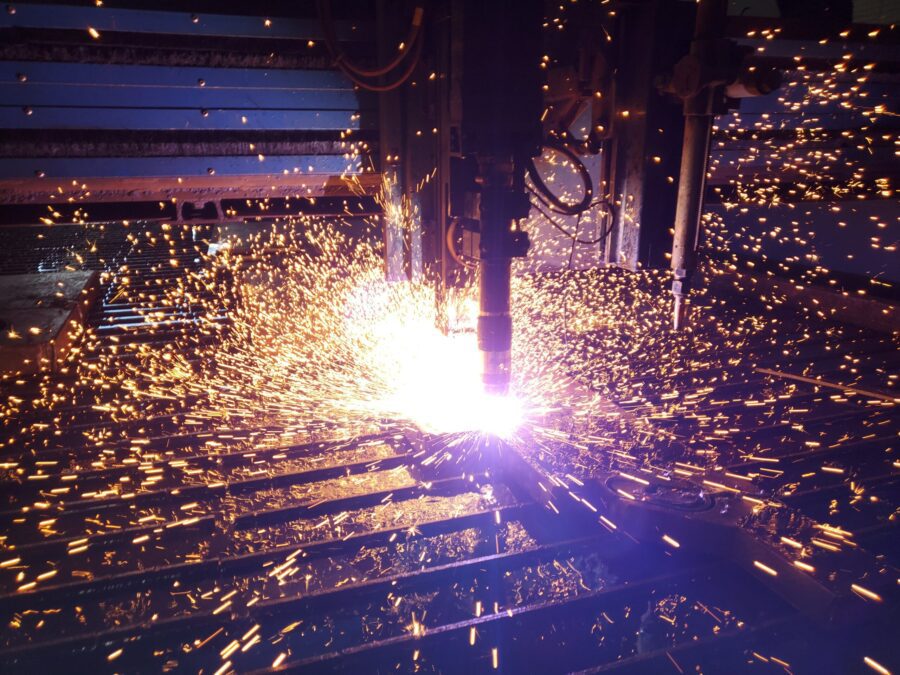

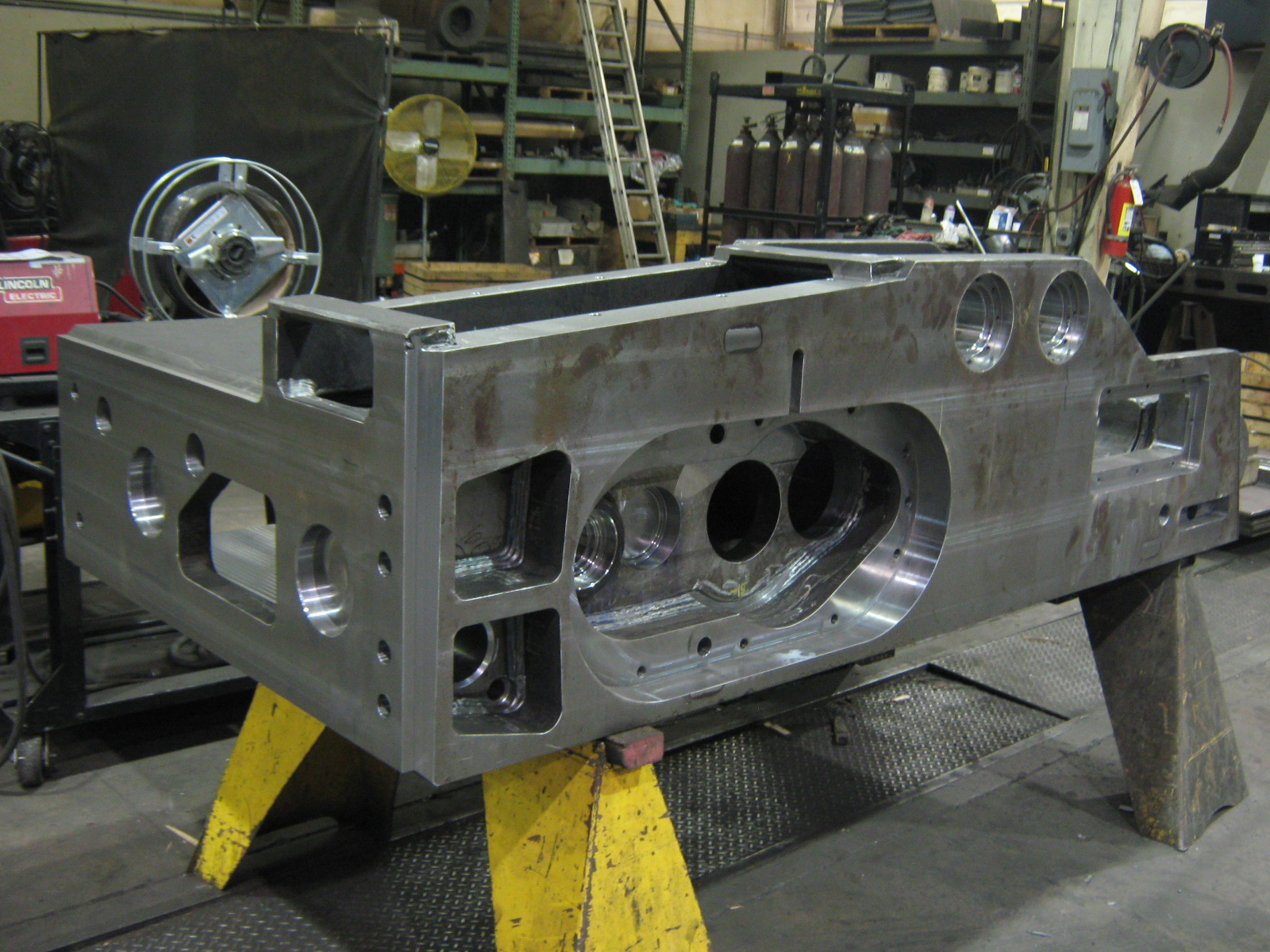

Our fabrication process involves cutting, bending, and assembling metal components to create robust and reliable structures. We utilize advanced cutting techniques, such as CNC plasma cutting and laser cutting, to achieve precise dimensions and intricate designs. Our state-of-the-art equipment allows us to perform complex bending operations with high accuracy, ensuring that each component fits perfectly.

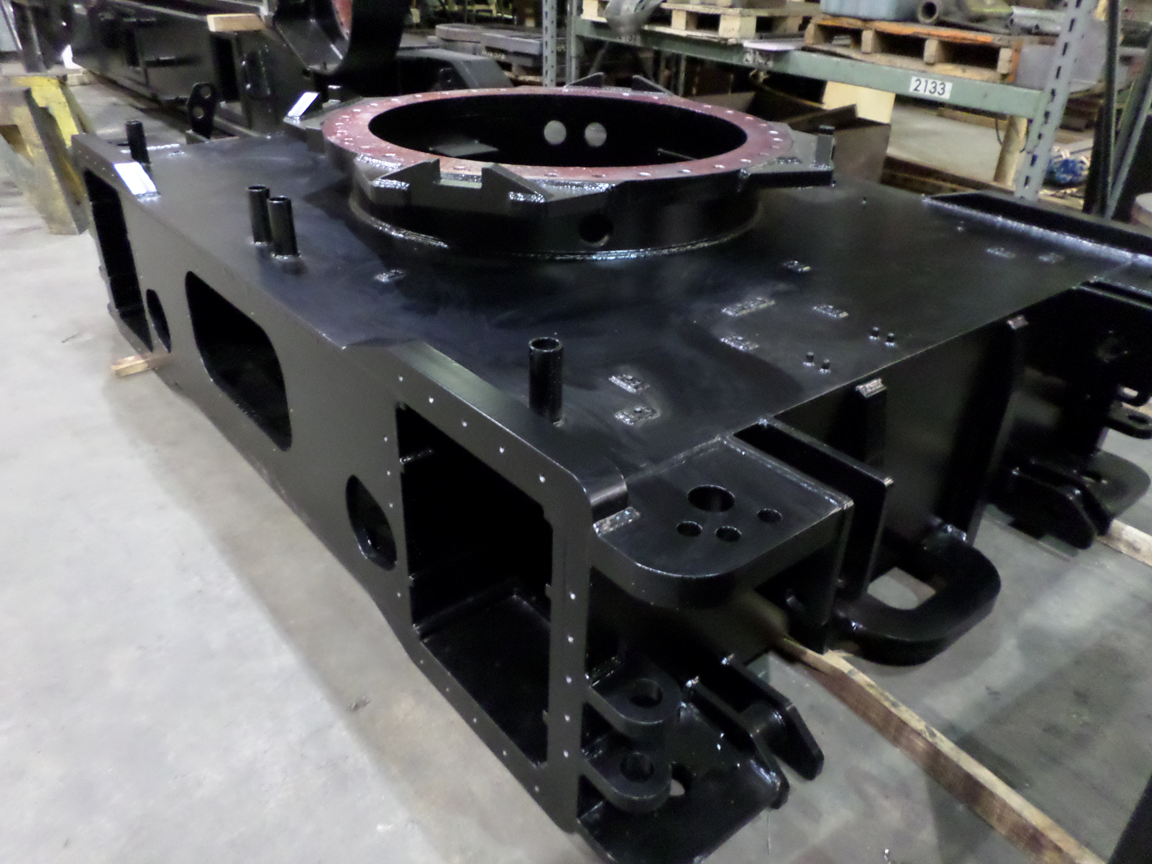

Once the pieces are prepared, our expert welders meticulously assemble and weld the components together. Using various welding techniques, including MIG, TIG, and stick welding, we ensure strong, durable connections that withstand the test of time. Throughout the fabrication process, we adhere to strict quality control measures, performing regular inspections and tests to guarantee the integrity and performance of each fabricated piece.

From custom metalwork to large-scale structural projects, our fabrication services deliver exceptional results that meet and exceed industry standards. Contact us today to discuss your fabrication needs and receive a quote for your project. Let Shaw Industries and Welding Technologies bring your vision to life with our expert fabrication services.